Baby Feeding Bottle

- Home

- Baby Feeding Bottle

- Features: lightweight, durable, low price, BPA-free, suitable for daily use.

- Transparency: PP material has relatively low transparency, usually presenting a translucent or opaque appearance.

- Heat-resistant temperature: up to about 110°C-120°C

- Service life: usually 6-12 months, depending on the frequency of use and cleaning method.

- Drop resistance: PP material has good drop resistance, is relatively light, and is suitable for daily use, but may have fine cracks or wear after multiple falls and long-term use.

- Durability: The durability of PP material is relative. It can handle daily use, but it will gradually age, discolor or deform over time and with repeated sterilization.

- Precautions: Avoid long-term high-temperature treatment (such as high-power heating in a microwave oven or long-term steam sterilization). Replace PP baby bottles regularly, especially when deformation or discoloration occurs, to keep it safe for use.

- Features: high heat resistance (can withstand 180°C-200°C), durable, not easy to age, is a high-end baby bottle material, at a higher price, does not contain BPA, and maintains stable performance during long-term use.

- Transparency: PPSU material has high transparency, presenting an amber or nearly transparent appearance, and the liquid in the bottle is clearly visible. Much clearer than PP material.

- Heat-resistant temperature: can withstand 180°C-200°C

- Service life: can be up to 1-2 years, or even longer, depending on conditions of use and maintenance.

- Drop resistance: PPSU material is very strong and has good drop resistance. Even in the case of frequent use and falling, its structural stability is high and it is not easy to crack or damage.

- Durability: PPSU is the most durable of the three materials. It can withstand repeated high-temperature sterilization and long-term use without significant aging or loss of performance, so it is a more high-end and durable choice among baby bottle materials.

- Precautions: PPSU is very safe for high temperature sterilization, microwave heating and daily use, and there is no need to worry about the release of harmful substances.

- Features: soft, high temperature resistant (above 200°C), anti-drop, comfortable to the touch, BPA-free, suitable for newborns and high-frequency sterilization.

- Transparency: Silicone baby bottles have low transparency and are usually milky white or translucent, which means that parents cannot easily see the amount of milk in the bottle directly. However, this may not be a problem for some parents, especially when the silicone baby bottle itself has other advantages (such as softness and durability).

- Food-grade silicone can withstand high temperatures of more than 200°C

- Service life: long, usually 1-2 years, depending on the frequency of use and maintenance methods.

- Anti-drop: Silicone baby bottles have excellent anti-drop properties. Because they are soft and elastic, they can effectively absorb impact and prevent the baby bottles from breaking or deforming. Compared with glass and plastic baby bottles, silicone baby bottles are very suitable for lively and active babies, and their anti-drop properties are stronger than PP and PPSU.

- Durability: Silicone has high anti-drop and durability characteristics, it is not easy to break or age, and it will not change color or deform even under repeated high-temperature sterilization. The soft material helps extend the service life.

- Precautions: Silicone material is safe under any common high-temperature sterilization or heating, and there is no need to worry about releasing harmful substances.

What are the quality standards for baby bottles?

1. Bottle quality standards:

International standards:

FDA certification (US Food and Drug Administration): Ensures that the bottle material meets the safety standards for food contact and does not release harmful chemicals during use.

EN 14350 (EU standard): Specifies the mechanical and chemical safety requirements for drinking and feeding equipment for infants and young children, ensuring that the material is stable in high temperature and acidic environments.

LFGB certification (German Food and Daily Necessities Law): Ensures that the bottle material does not release harmful substances when in contact with food, which is a stricter standard in the EU.

Chinese national standards:

GB 4806.1-2016 “National Food Safety Standard, General Safety Requirements for Food Contact Materials and Products”: Specifies the chemical and physical safety requirements for food contact materials to ensure that no harmful substances are released.

GB 4806.7-2016 “National Food Safety Standard Plastic Resins for Food Contact”: Specifies the migration limit and composition requirements for plastic materials for food contact.

GB 31604.1-2015 “National Food Safety Standard General Rules for Migration Test of Food Contact Materials and Articles”: Ensures that the migration amount of materials in food contact meets safety standards.

2. Common quality marks and certifications:

BPA-free mark: indicates that the baby bottle does not contain bisphenol A (BPA), which meets international and national health and safety requirements.

SGS certification: internationally recognized testing and certification to ensure that the baby bottle meets quality and safety standards.

TÜV certification: certification by the German testing and certification agency to ensure that the product meets EU and international safety standards.

ISO 9001: Whether suppliers and manufacturers meet international quality management system standards indirectly guarantees quality control of the production process.

3. How to verify that the baby bottle meets quality standards:

Check product labels and instructions: Confirm that the product is marked as compliant with FDA, CE, LFGB or GB standards, and mark the material type, such as PP, PPSU, Tritan, etc.

Request supplier test report: Request a test report issued by a third-party testing agency from the supplier to verify that the product meets relevant standards in terms of chemistry and physics.

Certification mark: Choose products with BPA-free mark, FDA-approved, CE mark, LFGB mark.

When choosing a baby bottle, you should choose the right material according to the usage requirements to ensure its heat resistance, durability and chemical stability. At the same time, you should check whether the baby bottle meets the relevant international and national quality standards, such as FDA, EN14350, LFGB and GB standards, and confirm that it does not contain harmful substances (such as BPA). Choosing products with certification marks and reliable test reports can better ensure their safety and quality.

When selecting suppliers, how do you ensure that their products meet international quality standards?

1. Check certifications and qualifications:

Certification verification: Ensure that the products provided by suppliers hold relevant international and national certifications, such as ISO9001 (quality management system), IS0 22000 (food safety management system), FDA certification (for the US market), CE certification (for the EU market), LFGB certification (for Germany) and GB standards (for the Chinese market)

BPA-free and other labels: Check whether the product is marked with “BPA-free” or other labels that do not contain harmful substances to verify product safety.

Certification documents: Request suppliers to provide copies or scans of these certifications to ensure that they are authentic and valid documents.

2. Obtain third-party test reports:

Third-party testing agencies: Request suppliers to provide third-party test reports issued by authoritative testing agencies such as SGS and TV. These reports should show that the product has passed relevant chemical composition tests, physical performance tests and compliance tests.

Key test content: Check the chemical migration, heat resistance, harmless chemicals (such as BPA, BPS, etc.) and other items in the report to confirm that the product will not release harmful substances at high temperatures and in daily use.

3. Review the supplier's production and quality management process:

ISO certification: Check whether the supplier has passed IS09001 and IS022000 certifications, which indicate that its production and management processes meet international standards and ensure the consistency of product quality.

Quality control procedures: Require suppliers to provide detailed descriptions of their production and quality control processes, such as whether there are multiple testing procedures, product sampling tests, and compliance reviews.

4. On-site inspection or virtual audit:

On-site inspection: Conduct an on-site inspection of the supplier in person or through a third-party agent to check its production facilities, production line equipment, and quality testing laboratories to confirm whether it meets international production standards.

Virtual audit: If an on-site inspection is inconvenient, you can ask the supplier to conduct a real-time video conference to demonstrate its production facilities and testing processes.

5. Sample testing:

Get samples: Before signing a long-term contract or purchasing a large order, ask the supplier to provide samples for testing in your own laboratory or through a third-party testing agency.

Test items: including heat resistance, chemical stability, physical durability and safety tests to verify whether the product meets the expected quality standards.

6. Customer evaluation and industry reputation:

Customer evaluation: Check other customers’ evaluation and feedback on the supplier, especially the experience of international customers who have worked with them, which can help determine whether their products meet the quality requirements in the international market.

Industry reputation: Choose suppliers with a good industry reputation and many years of experience, usually these suppliers have more complete compliance processes and quality management systems.

7. Clear contract terms and responsibilities:

Quality assurance clauses: clearly stipulate in the contract that the product must meet specific international and national quality standards, and list the acceptance criteria and testing procedures in detail.

Liability for breach of contract: stipulate the responsibilities that the supplier must bear if the product fails the test or does not meet the requirements (such as refund, return or re-supply).

8. Continuous supervision and evaluation:

Regular review: Regularly audit the supplier to check whether it continues to meet the certification standards and quality requirements.

Quality monitoring: Implement continuous quality monitoring, such as sampling testing or third-party inspections, to ensure that the long-term supply of products maintains consistent high quality.

In order to ensure that suppliers’ products meet international and national quality standards, buyers should use a combination of methods such as certification audits, third-party test reports, field visits, sample testing, and customer reviews. Clarifying contract terms and implementing regular supervision are also effective measures to ensure product quality and compliance. These steps can help you choose reliable suppliers, ensure that products meet the required standards, and ensure the safety and stability of baby products.

Our Service

We Support OEM&ODM

varieties of colors are available, you can customize the colors you need according to the Pantone color card

We provide customized printing services, including: screen printing, pad printing, thermal transfer, UV 3D color printing

blister, clamshell, pdg, color box, cardboard box.etc is available or we can also help you design the packaging

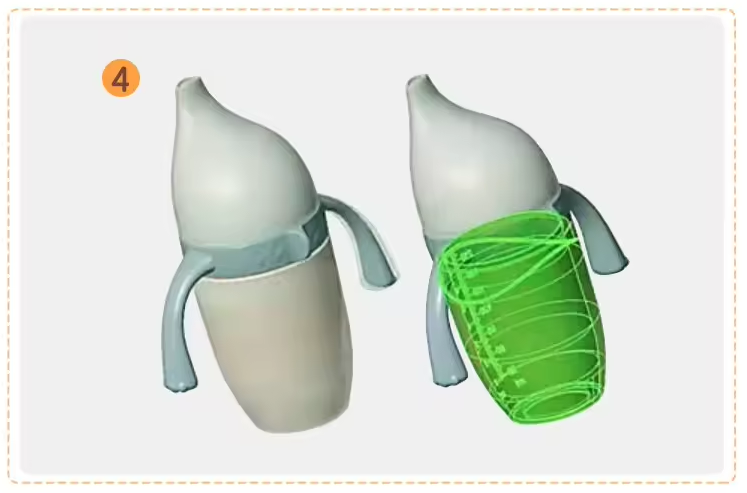

Customers can provide creative, our professional team provide 3D and rendering drawings, professional mold

Zhejiang Baohui Baby Product Co., Ltd.

Why Choose Us

Strong production capacity and international certification

BAOHUI has a modern 70,000 square metre production base with a daily delivery capacity of over 130,000 pieces, ensuring that large-scale orders can be met quickly and efficiently. We have passed ISO 9001, BSCI, FDA, LFGB, CPC, EN international certifications, and our products comply with international quality and environmental standards, ensuring quality stability and environmental compliance for each batch of products.

Flexible OEM/ODM customisation services

Whether it's OEM (Original Equipment Manufacturing) or ODM (Original Design Manufacturing), we offer comprehensive customised solutions for our customers. From design to production, our team of engineering design will assist you in creating unique products according to market demand and brand requirements, supporting personalised services such as multiple materials, color, logo printing, and packaging customisation.

Global Cooperation and Trusted Brands

BAOHUI has established long-term cooperation with famous brands such as BEABA, Bebebus, Baby Care, YEEYOO, TUMTUM, Lock&Lock, Smart Angel, Coconi, Nuby, etc. Our products are exported to more than 60 countries and regions such as Europe, America and Southeast Asia. With high quality products and excellent service, we have won the trust of global customers and become the long-term partner of many international brands.